Manipal Specialty Chemicals – Product Portfolio

Manipal Specialty Chemicals – Product Portfolio

At Manipal Specialty Chemicals, we offer a comprehensive range of high-performance emulsions, polymers, and dispersions engineered for the most demanding applications across packaging, printing, paints, and construction industries. Our products are developed with a deep commitment to performance, sustainability, and innovation.

WesttCryl N Series – Acrylic Polymer Emulsions

- Flexible Packaging

- |

- Inkjet Printing

- |

- Film Coatings

Products

N 101

N 101F

N 102

Acrylic copolymer binder

Pack size

50KG/200KG

Coating Methods

Core benefits

• Self-cross-linking chemistry

• Good clarity and barrier properties (Oil and Grease Resistance)

• Strong binding of pigments with various substrates

• Enhances colour strength

Product Specifications

Property

Value

Appearance

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Density 25 ‘C (g/сm3)

Light yellowish translucent liquid

43-45

50-150

7.0-8.0

1.05+0.04

Guideline Formulation

Raw Materials

Weight (%)

N101

Defoamer

Aq. NH3/MEA/DMEA

Wax Emulsion

Flow / Levelling Agent

Mar / Slip Additive

Biocide

Pigment Concentrate

Total

Dilution (IPA 70/Water 30)

65-70

0.1- 0.5

0.5-1.0

2.0-4.0

0.5-1.0

Upto 0.5

0.2

30-35

100

As Required

Usage Instructions

NA

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•Used as a binder in the formulation of waterborne flexographic and rotogravure printing inks for printing on paper, film, and Al foil.

Download

Acrylic copolymer dispersion

Pack size

50KG/200KG

Coating Methods

• Gravure /Reverse gravure

• Flexo

• Air-knife

Core benefits

• Self-cross-linking chemistry

• Indigenized technology co-created with the major film manufacturers

• Efficiently works at a lower deposition of 0.5-0.7 GSM at higher speed

• Works at a low surface energy of 38 dynes/cm

• Good clarity and barrier properties (Oil and Grease Resistance)

Product Specifications

Value

Appearance

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Density 25 ‘C (g/сm3)

Light yellowish translucent liquid

43-45

50-150

7.0-8.0

1.05+0.04

Guideline Formulation

NA

Usage Instructions

• The base substrate to be coated should have a minimum treatment level of 38 dynes/cm.

• Primer can be applied through different coating methods such as Gravure (direct/reverse), Flexo and Air knife.

• Recommended coat weight (dry) is between 0.5 to 1.0 g/m2

• Proper curing is recommended to get good adhesion with the substrate

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

• Suitable for surface printing on PE film

• Print-receptive primer for WB, UV, Solvent and Digital printing inks for transparent, metallized

Download

Neutralized, co-solvent free water-based acrylic dispersion

Pack size

50KG/200KG

Coating Methods

• Gravure /Reverse gravure

• Flexo

• Air-knife

Core benefits

• Low Seal Initiation Temperature (SIT) – 95 Deg C

• Good clarity

• Excellent printability with different printing processes

• Excellent antiblock properties

Product Specifications

Value

Appearance

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Density 25 ‘C (g/сm3)

White translucent emulsion liquid

25 – 26

25 – 50

9.5 – 10.5

1.05 ± 0.04

Guideline Formulation

NA

Usage Instructions

NA

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•Heat-seal coatings on Paper and paper board

Download

WesttCryl J Series – Styrene-Acrylic Dispersions

- Overprint Varnishes

- |

- Paper & Film Inks

- |

- Barrier Coatings

The WesttCryl J Series consists of specially designed emulsions for use in water-basedOPVs and printing inks. With options ranging from non-film forming to soft film-forming,the series provides customizable properties like gloss, rub-resistance, and flexibility.

Products

J 201

J 202

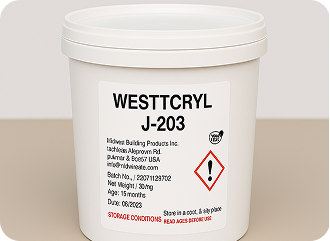

J 203

J 224

Non-film forming Styrene-Acrylic polymer emulsion

Pack size

20 kg , 50 kg and 220 kg

Coating Methods

NA

Core benefits

•Cost-effective emulsion

•Excellent gloss and optical clarity

•Fast drying

•High heat resistance

Product Specifications

Property

Value

Appearance

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Density 25 ‘C (g/сm3)

Molecular weight (Mw)

Acid value (mg KOH/g)

Glass transition temperature – Tg (°C) (with DSC)

Semi translucent Emulsion

46 – 48

350 – 550

8.0 – 9.0

1.05 ± 0.04

> 200,000

appr. 80

103

Guideline Formation

General Purpose OPV

Raw Materials

Weight (%)

WESTTCRYL J-201

Defoamer

Glycol Ether

PE wax emulsion

Silicon based Slip Additive

Water

IPA

83

0.2

4

5

0.1

4.2

3.5

FALSE

High Gloss High Slip OPV

Raw Materials

Weight (%)

WESTTCRYL J-201

WESTTCRYL J-202

Silicon based Defomer

Glycol Ether

Resin Solution (50%) from Joncryl 682

PE wax emulsion

Silicon based Slip Additive

Water

IPA

60

10

0.3

3.5

15

5

0.2

3

3

100

Flexographic printing ink for paper and paperboard

Raw Materials

Weight (%)

WESTTCRYL J-201

WESTTCRYL J-203

Pigment concentrate

Silicon based Defomer

PE wax emulsion Joncryl Glycol Ether

Water

35

15

40

0.5

5

1.5

100

Usage Instructions

NA

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•Binder for water-based overprint varnishes (OPV)

•Let-down vehicle for water-based flexographic and gravure-printing inks

Download

Film-forming Styrene-Acrylic copolymer emulsion

Pack size

20 kg , 50 kg and 220 kg

Coating Methods

NA

Core benefits

•Cost-effective emulsion

•Fast drying

•Excellent printability

•Excellent viscosity stability

Product Specifications

Property

Value

Appearance

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Density 25 ‘C (g/сm3)

Molecular weight (Mw)

Acid Value (on solids)

Glass transition temperature – Tg (°C) (with DSC)

Semi translucent Emulsion

45 – 47

400 – 700

8.0 – 9.0

1.05 ± 0.04

> 200,000

appr. 64

32

Guideline Formation

High Gloss High Slip OPV

Raw Materials

Weight (%)

WESTTCRYL J-201

WESTTCRYL J-202

Defoamer

Glycol Ether

Resin Solution (50%) from Joncryl 682

PE wax emulsion

Silicon based Slip Additive

Water

IPA

60

10

0.3

3.5

15

5

0.2

3

3

100

Usage Instructions

NA

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•Film-forming binder for water-based overprint varnishes

•Let-down vehicle for water-based flexographic and gravure-printing inks

Download

Film-forming Styrene-Acrylic copolymer emulsion

Pack size

20 kg , 50 kg and 220 kg

Coating Methods

NA

Core benefits

•Cost-effective emulsion

•Fast drying

•Excellent printability

•Excellent viscosity stability

Product Specifications

Property

Value

Appearance

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Density 25 ‘C (g/сm3)

Molecular weight (Mw)

Glass transition temperature – Tg (°C) (with DSC)

Acid value (mg KOH/g)

Semi translucent Emulsion

46 – 48

500 – 850

8.0 – 9.0

1.05 ± 0.04

> 200,000

-8

Approx. 48

Approx. 48

Guideline Formation

Deep Freeze Resistance OPV

Raw Materials

WEIGHT (%)

WESTTCRYL J-203

Defoamer

PE emulsionon

IPA

Water

90

0.2

0.5

2

7.3

100

Flexographic printing ink for paper and paperboard

WESTTCRYL J-201

WESTTCRYL J-203

Pigment concentrate

Silicon based Defomer

PE wax emulsion

Glycol Ether

Water

35

15

40

0.5

5

3

1.5

100

Usage Instructions

NA

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•Film-forming binder for water-based overprint varnishes

•Let-down vehicle for water-based flexographic and gravure-printing inks

•Functional packaging coatings for barrier or film/foil applications

Download

Rheology-controlled soft film-forming acrylic emulsion

Pack size

50 kg and 220 kg

Coating Methods

NA

Core benefits

•Excellent gloss,

•Very high flexibility,

•Very good adhesion to a wide variety of substrates,

•Good water and rub resistance

Product Specifications

Property

Value

Appearance

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Density 25 ‘C (g/сm3)

Molecular weight (Mw)

Glass transition temperature – Tg (°C) (with DSC)

Acid value (mg KOH/g)

Semi translucent Emulsion

46 – 48

500 – 850

8.0 – 9.0

1.05 ± 0.04

> 200,000

-8

Approx. 48

Approx. 48

Guideline Formation

NA

Usage Instructions

NA

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•Let-down vehicle for water-based flexographic and gravure printing inks, especially for film substrates.

•Offers an optimal balance of properties for surface printing and adhesive lamination applications

Download

WesttCryl OP Series – Opaque Polymers

- Paints & Coatings

- |

- Cost-Effective Opacity

- |

- TiO₂ Replacement

Products

OP 401

Advanced Water-based Styrene-acrylate Copolymer Emulsion

Pack size

50KG/220KG

Coating Methods

NA

Core benefits

• Lowers TiO2 demand and formulation cost

• Provides increased light-scattering for improved hiding properties

• Excellent formulating efficiency

• Low VOC and Low Odor

Product Specifications

Value

Appearance

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Density 25 ‘C (g/сm3)

Opaque, white to off-white emulsion

30-32

100 – 500

9.0 – 10.0

1.04+/-0.01

Guideline Formation

NA

Usage Instructions

NA

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•Used as a partial replacement, a maximum of 10-15% by weight to TiO2 in coating applications.

• It is a non-film forming high Tg emulsion. Suitable coalescing agents can be required for achieving film formulation at the required temperature.

Download

WesttCryl C Series - Colloidal Emulsions

- Corrugated Inks

- |

- Kraft Paper Printing

- |

- Alkali-Resistant Systems

Products

C 301

C 368

C 301 An Aqueous Acrylic Colloidal Emulsion

Pack size

50 KG |220 KG

Coating Methods

NA

Core benefits

•Excellent transfer,

•very good printability,

•low cost in use,

•excellent colour strength development.

Product Specifications

Value

Appearance

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Density 25 ‘C (g/сm3)

Glass transition temperature – Tg (°C) (with DSC)

Opaque Emulsion

39 – 41

15 – 50

5.0 – 6.0

1.05 ± 0.04

26

Guideline Formation

Raw Materials

Weight (%)

Westtcryl C-301 neutralization

Westtcryl C-301

MEA

Water

Viscosity (Brookfield) @ 25 ᴼC

pH

59.2

2.95

37.85

100.0 Parts

±1900

8.6 ± 0.1

Flexographic ink for corrugated inks and kraft paper substrates

Raw Materials

Weight (%)

Westtcryl C-301 neutralization

Pigment concentrate

PE wax emulsion

Defoamer

Water

55

35

5

0.5

4.5

100

Usage Instructions

NA

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•Let-down vehicle for post-print inks for kraft paper and corrugated board.

•It can be used to thicken water-based gravure and flexographic inks

Download

C 368 An Aqueous Acrylic Colloidal Emulsion

Pack size

50 KG |220 KG

Coating Methods

NA

Core benefits

•Excellent transfer,

•very good printability,

•low cost in use,

•excellent colour strength development.

Product Specifications

Value

Appearance

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Acid value (mg KOH/g)

Density 25 ‘C (g/сm3)

Glass transition temperature Tg (DSC)

Opaque Emulsion

41 – 43

< 50

3.5 – 4.5

160 – 180

119

1.03 ± 0.04

Guideline Formation

NA

Usage Instructions

NA

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•Let-down vehicle for post-print inks for kraft paper and corrugated board.

•It can be used to thicken water-based gravure and flexographic inks

Download

WesttCryl PU Series – Polyurethane Dispersions

- Premium Finishes

- |

- Waterproofing

- |

- Film & Fabric Coatings

Our WesttCryl PU Series comprises aliphatic waterborne polyurethane dispersions for durable coatings, ink binders, and functional surface finishes. These PUDs offer enhanced scratch resistance, chemical durability, and tactile aesthetics like velvetand smooth matt finishes.

Products

PU 501

PU 502

PU 503

An aliphatic waterborne polyurethane dispersion

Pack size

120 KG I 220 kg I 1000 KG

Coating Methods

• Gravure /Reverse gravure

• Flexo

• Air-knife

Core benefits

•Excellent adhesion

•Good ink receptivity

•Works at a low surface energy of 38 dynes/cm

Product Specifications

Value

Appearance

Resin Type

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Glass transition temperature Tg (DSC)

Semi-translucent

Anionic

37-39

10 – 30

7.0 – 9.0

-20

Guideline Formation

NA

Usage Instructions

•The base substrate to be coated should have a minimum treatment level of 38 dynes/cm.

•Coating can be applied through different coating methods such as Gravure (direct/reverse), Flexo etc.

•Proper curing is recommended to get good adhesion with the substrate

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•Ink-receptive primer for WB and UV printing inks

•Designed for filmic primer application

Download

An aliphatic waterborne polyurethane dispersion

Pack size

120 KG I 220 kg I 1000 KG

Coating Methods

• Gravure /Reverse gravure

• Flexo

• Air-knife

Core benefits

•Low gloss, Excellent Velvet hand feel

•Good Scratch/Rub resistance

•Excellent adhesion on PET/BOPP film

Product Specifications

Value

Appearance

Resin Type

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Milk white liquid

Anionic

36-38

500 – 1500

7.0 – 9.5

Guideline Formation

NA

Usage Instructions

•The base substrate to be coated should have a minimum treatment level of 38 dynes/cm.

•Product can be thinned with either water or 1:1 mixture of water & IPA.

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•This product provides a Velvet feel with matt appearance on various substrates such as PET, BOPP, Paper, and Paper board

Download

An aliphatic waterborne polyurethane dispersion based on polyester

Pack size

200 kg I 1000 KG

Coating Methods

NA

Core benefits

•Good Tensile strength, wear resistance,

•Weather resistance

•Water resistance

•Good elongation

Product Specifications

Value

Appearance

Resin Type

Non_Volatile(%)

Viscosity at 25’c (mPa-s)

pH

Elongation

Tensile strength (Mpa)

100% Modulus (Mpa)

Yellowing resistance

Glass transition temperature Tg (DSC)

Translucence-white

Anionic

58-61

<1000

7.0 – 9.5

2600-2700

3.3

0.3

Non Yellowing

-3

Guideline Formation

(In progress)

Usage Instructions

NA

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Applications

•High solid polyurethane dispersion. It has good mechanical properties and weather resistance, water resistance, and wear resistance. It has soft film, good elasticity, and high elongation. Suitable for elastomeric construction coatings

Download

WesttCryl P Series - Styrene-Acrylic Dispersions

- Overprint Varnishes

- |

- Barrier Coatings

- |

- Paper & Film Inks

Products

C 301

C 368

Acrylic copolymer dispersion

Pack size

50KG/150KG

Coating Methods

- Strong bond to flexible and metalized films

- Oil and grease resistance with high print clarity

- Excellent water resistance and ink stability

- Versatile usage across WB, UV, and solvent-based systems

Applications

- Suitable for surface printing on PE film

- Print-receptive primer for WB, UV, Solvent and Digital printing inks for transparent, metallized

Guideline Formation

Appearance

Viscosity at 25’c (mPa-s)

Non_Volatile(%)

pH

Density 25 ‘C (g/сm3)

Light yellowish translucent liquid

43-45

50-150

7.0-8.0

1.05+0.04

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Acrylic copolymer dispersion

Pack size

50KG/250KG

Coating Methods

- Strong bond to flexible and metalized films

- Oil and grease resistance with high print clarity

- Excellent water resistance and ink stability

- Versatile usage across WB, UV, and solvent-based systems

Applications

- Suitable for surface printing on PE film

- Print-receptive primer for WB, UV, Solvent and Digital printing inks for transparent, metallized

Guideline Formation

Appearance

Viscosity at 25’c (mPa-s)

Non_Volatile(%)

pH

Density 25 ‘C (g/сm3)

Light yellowish translucent liquid

43-45

50-150

7.0-8.0

1.05+0.04

Handling and Storage

• The product must be stored at 5-40 °C temperature. Do not restore the contaminated material to the original container or reuse it.

• According to the storage guidelines provided above, the product has storage

Coming soon

Flexible Packaging

Empowering Flexible Packaging with Performance and Beauty.

Applications

- Ink-receptive primers for BOPP, PET, PE, OPP films

- Surface printing on PE films

- Heat-seal coatings for flexible laminates

- UV inkjet printable coatings

- Velvet-feel, matt appearance coatings for premium pouches and laminates

Deliver vivid prints, stronger bonds, and an unforgettable tactile experience — with Manipal Specialty Chemicals.

Recommended Products

WesttCryl N 101

WesttCryl MPU 502

WesttCryl MPU 501

WesttCryl N 102F

WesttCryl N 101F

Food Packaging

Deliver vivid prints, stronger bonds, and an unforgettable tactile experience — with Manipal Specialty Chemicals.

Applications

- Barrier primers for food-grade Al foil and metallized films

- Heat-sealable coatings for printed food wraps and flexible packs

- Ink-receptive primers for food contact materials

Where safety meets performance — trusted solutions for the food industry's packaging needs.

Recommended Products

WesttCryl MPU 501

WesttCryl N 101F

WesttCryl N 101

Labeling

Making Every Label Count — Precision, Durability, and Style.

Applications

- Printable primers for In-Mold Labels (IML)

- Coatings for Pressure-Sensitive Labels (PSL)

- UV, solvent, and water-based ink compatibility for label films

Achieve bold, durable labels that enhance brand identity — with Manipal Specialty Chemicals.

Recommended Products

WesttCryl N 101F

WesttCryl MPU 501

Paper-Based Packaging

Strengthen Every Sheet. Elevate Every Impression.

Applications

- Overprint varnishes for folding cartons, rigid boxes, and luxury packaging

- Post-print flexographic inks for kraft and corrugated board

- Durable, water-resistant coatings for shipping and storage cartons

Our specialty binders ensure outstanding gloss, durability, water resistance, and flexibility for paperboard and corrugated packaging solutions.

Recommended Products

WesttCryl C 301

WesttCryl J 203

WesttCryl J 202

WesttCryl J 201

Construction Chemicals

Coat. Protect. Endure.

Applications

- Partial TiO₂ replacement in decorative and industrial paints

- Waterproofing membranes and protective barriers

- Elastomeric coatings for roofs, walls, and fabrics

- Scratch-resistant, weather-resistant coatings for construction materials

Build smarter, longer-lasting structures — with the performance advantage of Manipal Specialty Chemicals.

Recommended Products

WesttCryl MPU 503

WesttCryl OP 401

Printing & Packaging Inks

Enabling Exceptional Prints — Across Paper, Board, and Films.

Applications

- Water-based overprint varnish binders for paper and board

- Flexographic and gravure ink vehicles for flexible packaging

- Barrier coatings for film and foil substrates

- High-adhesion binders for alcohol-resistant ink formulations